Langford Metal Industries in Brisbane is a leading precision sheet metal fabricator known for their superior quality and finishes. With our extensive experience and expertise, we are capable of producing a wide range of metal products.

Langford Metal Industries in Brisbane is a leading precision sheet metal fabricator known for their superior quality and finishes. With our extensive experience and expertise, we are capable of producing a wide range of metal products.

Sheet Metal Fabrication Brisbane

We are the longest established precision leaders in sheet metal fabrication. Langford Metal Industries excels in superior finish and quality. With over 70 years of experience, we know what it means to be a high-quality, trustworthy supplier of fabricated metal products and steel fabrication in Brisbane.

Our reliable services are comprehensive and efficient as we can cut, mend, and forge your metal to produce the structures you want with your own given design. Our fully customisable sheet metal fabrication system ensures that you’re in control every step of the way.

Metal Fabrication Brisbane

Langford Metal is a precision sheet metal fabrication, laser cutting, turret punching, CNC bending and plasma cutting specialist. Whatever you need created with metal, we have the experience, capability and know-how to produce it.

From one-off construction components to mass-produced automotive parts, industrial equipment, commercial kitchens, power supply components, street furniture and more, we are one of Queensland’s most extensive and longest-serving metal manufacturers and fabricators. Our years of knowledge and expertise in the area has allowed us to master the Brisbane steel fabrication process for a variety of different uses and therefore, we’re your go-to business when you need metal products that last.

With a dedicated, skilled workforce and continuous investment in new machine technology, Langford Metal is perfectly placed to bring your sheet metal requirements to life accurately, in time and on budget.

Your Trusted Steel Fabrication Brisbane Experts

Are you in search of reliable steel fabricators near you? Look no further! Langford Metal is your trusted source for steel fabrication in Brisbane. With our extensive experience and expertise, we are here to solve all your steel fabrication needs. When it comes to steel fabrication, finding a reliable and skilled team can be a challenge. You need professionals who can deliver high-quality results that meet your specifications.

Don’t settle for subpar steel fabrication services. Low-quality work can lead to delays, additional costs, and compromised project outcomes. At Langford Metal, we specialise in steel fabrication in Brisbane, including the southside and northside regions. With our state-of-the-art facilities and dedicated team, we ensure superior craftsmanship and timely project delivery.

Choose Langford Metal for custom stainless steel fabrication in Brisbane. We have a proven track record of producing exceptional results, satisfying our clients’ requirements, and exceeding their expectations.

Contact us today to discuss your steel fabrication project. Experience the Langford Metal difference and let us provide you with an estimate that meets your needs and budget. Don’t settle for less when it comes to your steel fabrication requirements. Trust Langford Metal for excellence in every aspect of the process.

EXTENSIVE

METAL PROCESSING

CAPABILITIES

At Langford Metal, we specialise in a variety of processing and custom metal fabrication services which includes the following:

Our Unique

Fabrication Process

Metal fabrication is the creation of metal parts, products and structures using cutting, metal bending and assembling processes. The stages involved in creating the perfect steel fabrication to meet our clients’ expectations are more detailed. At Langford Metal this typically involves:

SPECIFICATION

At Langford Metal, we allow for customised fabrication and therefore, we work with you one on one tounderstand exactly what you want created and how we can use our years of experience and expertise to produce your desired product. We work to your specifications to create the steel fabrication to fit your needs.

DESIGN

Before we fabricate your material, we’ll ensure that we understand what design you’re after and know how to perfect it. Our team specialise in the design process and can turn your design dream into a reality.

REVIEW

We continuously review our steel fabrication process to ensure everything is working as it should be. We pride ourselveson our dedication to our customers and making sure that they are getting exactly what they want. Therefore, we evaluate the product design and specification and continue the reviewing process throughout the fabrication procedure.

PROTOTYPING

Before we make a start on your final product, we take the extra step the create a prototype to figure out how your product or structure will look, work, and be presented. Once you’re happy with the prototype, we’ll continue the sheet metal fabrication process to produce the final structure.

PROGRAMMING

With our use of CNC and modelling technology, we can utilise programming to ensure your files are optimised for an impressive manufacturing result. We understand that precisions and meticulous detail makes all the difference and therefore, we make sure we rise above our competitors through our programming stage of the sheet metal fabrication process.

MANUFACTURE

The final stage of the steel fabrication process where we utilise cutting, bending, and assembling processes to create the product or structure you want. We’ll join separate parts together and finalise the procedure through the manufacturing process. Once we’ve completed each step of our custom fabrication process, you’ll receive your product.

Our Work Includes

Fuel Tanks | Gym Equipment | Switchboard Cabinets | Decorative Screens | Ute Trays | Control Boxes | Mining Equipment | Automotive | Commercial Cooking Equipment | Balustrading | Door Frames | Industrial Ducting | Machine Components | Electrical Componentry | Tables | Stands | Angle Iron Frames | Outdoor Furniture | and much more

Recent

post

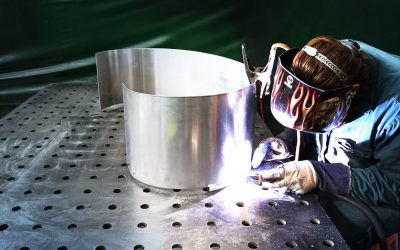

Sheet Metal Welding: Common Methods and Tips

Mastering the art of sheet metal welding is essential in transforming rudimentary metal components into functional, precise creations. Crafting metal components into the desired dimensions is the initial step. The subsequent task involves melding these pieces together...

How to Weld Stainless Steel Metal: A Complete Guide

Stainless steel is a popular building material known for its long durability and corrosion-resistant properties. However, achieving successful welds on stainless steel can be a challenging task. This guide discusses how to weld stainless steel to ensure structural...

Sheet Metal Welding: Common Methods and Tips

Mastering the art of sheet metal welding is essential in transforming rudimentary metal components into functional, precise creations. Crafting metal components into the desired dimensions is the initial step. The subsequent task involves melding these pieces together...

How to Weld Stainless Steel Metal: A Complete Guide

Stainless steel is a popular building material known for its long durability and corrosion-resistant properties. However, achieving successful welds on stainless steel can be a challenging task. This guide discusses how to weld stainless steel to ensure structural...

The Advantages of Stainless Steel for Custom Fabrication Projects

Stainless steel fabrication is the process of creating custom metal pieces from raw or stock stainless steel material. The fabrication method differs depending on specific industrial needs. This specialised process creates a wide range of products - from architectural...

Get in touch

When you search for “metal or steel fabrication near me,” look no further than Langford Metal. We are conveniently located to serve the entire Brisbane area. As leading steel & metal fabricators in Brisbane, including southside areas, we deliver superior results.

Do you have an upcoming project that you need our expertise on? With our metal fabrication services, we can cut, forge, and bend materials to suit your needs. We have years of experience in the sheet metal fabrication industry and understand what it means to deliver products that last. For more information on our services, contact us today or call us on 07 3088 9274.

Email: sales@langfordmetal.com.au

Address: 44 Curtin Avenue West, EAGLE FARM, QLD 4009.

Get in touch

Phone: 07 3088 9274

Email: sales@langfordmetal.com.au

Address: 44 Curtin Avenue West, EAGLE FARM, QLD 4009.

ABOUT US

Langford Metal has been producing superior fabricated metal products in Brisbane since 1955. Family owned, our extensive capabilities and reputation for service and finish excellence mean we can create virtually anything in metal, under one roof. Longstanding clients continue to rely on our quick turnaround and skilled workforce. So, whether it’s large or small, a one off, or mass production requirement, whatever you want producing in metal contact us today for an estimate.

FAQs

What is metal sheet fabrication?

What are the types of fabrication?

There are many types of fabrication processes, but the most common are:

- Cutting: aside from using a standard saw, metal fabricators can also cut metal with plasma torches, water jets, and lasers.

- Casting: this is the process in which molten metal is poured into a die. It is useful for creating identical multiples of the same product.

- Welding: welding connects two pieces of metal together using fusion.

- Stamping: using a press, stamping creates indentations and raises metal in specific shapes.

- Punching: Like stamping, punching also uses a press, but instead of creating indentations, punching cuts out holes in the metal.

- Folding: folding metal is a complicated process and requires specific equipment

- Shearing: this is the process used to make long cuts in metal. It is often used for sheet metal.

How much does fabrication cost?

To get an accurate quote on how much your fabrication project may cost you, contact Langford Metal today. We can connect you with a team member who can help estimate the cost of your job.

What does it mean to fabricate metal?

What is the difference between welding and metal fabrication?

Aside from welding, metal fabrication also includes cutting, stamping, pressing, bending, and many more. Each technique is used to transform the metal differently, depending on the desired finished product.

Welding involves the fusing of two separate pieces of metal. It consists of highly specialised tools and requires a lot of training and practice to master.