I’ve been playing around with electronics for a while, making do with my trusty breadboard for prototypes, and occasionally some veroboard if I wanted something more permanent. Unfortunately times are changing, and fewer and fewer interesting components are being made available in breadboard-friendly DIP packages (I blame Apple for convincing everyone that all electronic gadgets should be the size of a credit card).

This had been frustrating me for a while, but came to a head on my latest project where I needed an I2C level converter. Despite many wasted afternoons scouring octopart, digikey and mouser I came up empty handed, so decided it was about time I figured out this surface mount thing.

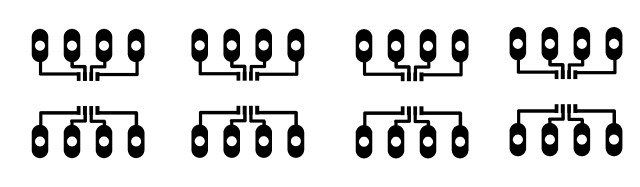

As it turned out, it was all pretty straightforward, though I did have to buy quite a lot of new equipment. Here’s my first surface mount PCB (a 0.5mm pitch DCU to DIP adapter for a TXS0102):

It’s worth pointing out that you don’t have to go the full PCB etching route like I did. Sparkfun have a number of adapter boards which break out surface mount packages to DIP. These look great for a quick prototype, but I’d been meaning to try PCB manufacturing for a while, so I thought I’d give it a go.

There’s a couple of popular ways to go about making your own PCBs. The first, and cheapest is the toner transfer method. This involves printing your circuit onto photo paper with a laser printer, then transferring the toner directly to your PCB using heat and pressure. The toner can then be used as a normal acid resist. The method sounds good however there are a lot of reports of people having mixed success, and it looks like it requires a lot of experimentation to find the right combination of laser printer, paper, and transfer method.

The second method is the standard photo sensitive resist technique. This is more expensive, but potentially more reliable, which sounded good to me. Here’s the steps I went through to create my first surface mount PCB:

- Create the PCB image.

Eagle is a schematic editor which is free for non-commercial use (though it does feel a bit like 1997). Sparkfun have a good tutorial on using it which is worth checking out. To create the final image, just use File -> Export…-> Image, rather than generating the gerber files as described in the tutorial. Here’s my image:

I created four copies of the board layout so I could experiment with different exposure times in a later step.

I created four copies of the board layout so I could experiment with different exposure times in a later step. Getting hold of land patterns can be difficult for some components. The ‘smd-ipc.lbr’ library which comes with Eagle has many standard patterns. Sparkfun also have their own Eagle library which you can download from here. Failing those options, you can manually create the land pattern if you can find a datasheet which describes it (which is what I ended up doing for the TXS0102).

Getting hold of land patterns can be difficult for some components. The ‘smd-ipc.lbr’ library which comes with Eagle has many standard patterns. Sparkfun also have their own Eagle library which you can download from here. Failing those options, you can manually create the land pattern if you can find a datasheet which describes it (which is what I ended up doing for the TXS0102).

- Print it onto acetate or polyester

The Kinsten website claims that a sheet of translucent polyester gives better contrast than transparent acetate because the polyester absorbs more of the ink than the acetate. I used the polyester sheets and got good results with tracks 0.2mm wide, and I suspect it would probably go even smaller. I had the misfortune to only own an ink jet printer (Canon MP600) and despite trying a bunch of different printer settings I couldn’t get a high contrast image (basically the ink wouldn’t dry), so I ended up trekking down to the local print shop and using their fancy laser printer.Update 4/3/12: I bought a Samsung Ml-1865 monochrome laser printer from Office Works for about $70, which works well.

- Expose the photo-sensitive PCB

UV exposure boxes are pretty expensive, however I found a relatively cheap one at Kinsten (product code ALT-UV). Oddly enough, the packaging indicated it was actually a UV finger nail drying machine. It also came with 3 x 15 watt UV tubes which are supposed to have a wavelength which matches the photo sensitive resist. Here it is in action:

The exposure process is pretty simple: peel off the plastic backing from the photo sensitive PCB, lay the printed polyester face down on top, place a layer of glass on top (to keep it flat), then slide it into the UV exposure box. I used 4 copies of my circuit, and exposed each for a different time to find the optimum exposure time. The 4 copies were exposed for 75, 100, 150, and 200 seconds respectively. The optimum looks to be about 100 seconds.

The exposure process is pretty simple: peel off the plastic backing from the photo sensitive PCB, lay the printed polyester face down on top, place a layer of glass on top (to keep it flat), then slide it into the UV exposure box. I used 4 copies of my circuit, and exposed each for a different time to find the optimum exposure time. The 4 copies were exposed for 75, 100, 150, and 200 seconds respectively. The optimum looks to be about 100 seconds.

- Develop the photo resist

After exposing the PCB to the UV the next step is to immerse the board in developer solution. After about 30 seconds the green photo resist that was exposed to the UV starts coming off into the solution (it looks a bit like blue smoke), eventually leaving just the photo resist that was masked by the polyester. Once it has developed sufficiently you have to rinse it off with water to stop the reaction. Here’s the board: You can see the traces get thinner from left to right (reflecting greater exposure times).

You can see the traces get thinner from left to right (reflecting greater exposure times).

- Acid Bath!

The fun part. To work well the etchant needs to be heated to 50-60°C and be continuously agitated. Without these conditions, the reaction will take a lot longer and may undercut the copper around the resist. Kinsten sell a kit with a heater, thermometer and air pump (I promise I don’t get kickbacks from Kinsten), though you could probably get a way a plastic tub, kettle, and a plastic spoon. As the reaction progressed the solution turned a faint blue color. After about 6 minutes the copper not protected by the resist vanished, leaving the traces still covered in green acid resist. Once this looks finished, rinsing the board off in water stops the reaction.

- Remove the resist

The last step is to remove the resist from our copper traces. An easy way to do this is to expose the board to UV for a couple of minutes and then dip it into the developer solution we used earlier. Other people just scrub it off, but I hate the idea of damaging the traces after this much work. Here’s the final result:

- Neutralizing the developer and etchant

To prevent dissolving my landlord’s plumbing I bought some neutralizing kits from, you guessed it, Kinsten. Unfortunately they didn’t come with directions, however I can recommend not dumping the powder directly into the solution or it will heat up, do nasty things to your brand new plastic tank, and scare your wife. So I hear, anyway. <Shuffles feet>

UPDATE 4/3/2012

Since writing this article I’ve made a couple of dozen boards, and have the process working pretty reliably now. Most of the early problems I had were caused by the film not lying perfectly flat on top of the PCB. Often this was caused by the PCB being slightly warped, or having a slight burr on an edge, caused by the cutting process. I’ve tried a number of different cutting techniques in an attempt to minimize this:

- Tin Snips

These produce straight cuts quite quickly, but tend to warp the board badly, and can de-laminate the PCB near the edge. - Hack Saw

Messy, quite time consuming, and can be difficult to produce perfectly straight edges. Doesn’t warp the board, but can leave burrs on the edge which need to be filed down afterwards. - Score-and-snap

This is the method I use most of the time: clamp a steel ruler on top of the PCB with one edge lined up to where you want the cut to be. Score it a dozen times with a blade (with a lot of pressure). Flip the board over and do the same thing on the other side, being careful to align the cuts on both sides of the board. Snap the board, either over the edge of the desk, or with a clamp. The edge normally needs to be cleaned up a bit with a file. This is time consuming, but produces straight cuts and doesn’t usually warp the board.

Even with a perfectly flat board I would often get fuzzy regions. My first attempt to fix this was to use a weight to push the board, film, and glass sheet together. To do this I had to flip the UV enclosure upside down, then place the sheet of glass on top, followed by the film, the PCB, and a weight (usually some books about the same size as the PCB).

This worked much better than previously, but still wasn’t perfect. It turned out that the extra weight was causing the glass to bend slightly (I was using some glass from a cheap photo frame), which would cause the film and PCB to separate in some places, causing the fuzzy patches. The solution was to get some thicker glass. I ended up buying a 200mm x 200mm x 5mm piece of glass from a local glass shop, which doesn’t bend visibly, even with a couple of old university text books on top. Note that the exposure time will need to increase due to the glass and the extra distance from the UV source.

Excellent guide

Ive just purchased the UV box, and have bad results, so, fingers crossed.

Rich

Sorry to hear its not working for you. I’ve added a section at the bottom of the article with some of the changes I’ve made to my process since writing it, which might help you. What problems are you having?

The transfer is hardly noticible, when etched, it basically etches away. Ive tried various times, even 10 minutes.

I just cant get a nice, visible transfer.

Im using Laser @600dpi, transparent sheet, glass sheet, and unit you have above, 36watt total,

Im at present making UV LED baord with 100 UV LEDS, so ill see if i can get some results there

Thanks for help

It sounds like the board is being over exposed. You could try exposing it for shorter times (try 30, 60, and 90 seconds). Another possibility is that the board is being exposed to UV before or after the actual exposure – eg from a window. The only other thing I can think of is that the traces aren’t dark enough – make sure your printer is setup for maximum darkness. I use the polyester sheets from kinsten rather than transparent sheets – apparently they give higher contrast.